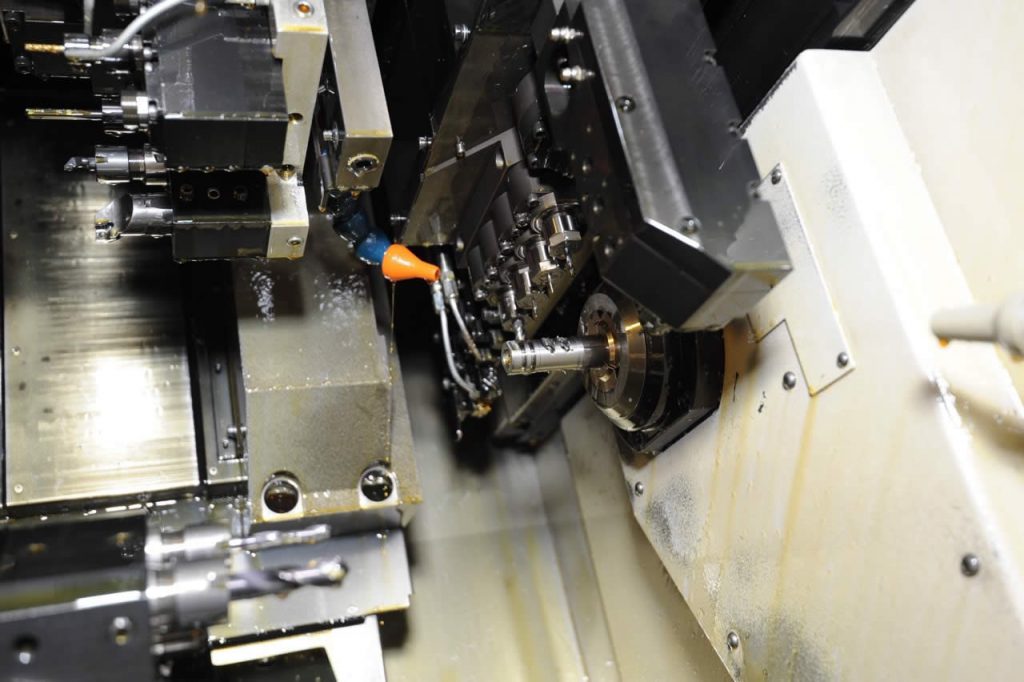

As the largest capacity Precision Turned Components manufacturer in the US, Swiss Automation is capable of small or large volume runs with short lead times, due to our ability to run production 24 hours / 7 days a week. We currently employ over 300 qualified people dedicated to delivering on our customers’ ever dynamic needs.

Machine List

- 7 Citizen A2-20VII – 3/4″ capacity

- 3 Citizen A32VII – 1 1/4″ capacity

- 20 Citizen K16 (K16VII, K16E) – 5/8″ capacity

- 6 Citizen L12 – 1/2” Capacity

- 10 Citizen L20 (Type IX, VII, X) – 3/4″ capacity

- 2 Citizen L32 Type XII – 1 ¼” capacity

- 29 Citizen M16 (M16, Y-axis, Y&B Axis) – 5/8″ capacity

- 21 Citizen M20 (M20, Y-axis) – 3/4″ capacity

- 32 Citizen M32, (M32, Y-axis, Y & B-axis) – 1 1/4″ capacity

- 1 Citizen D25, (Y-axis, B-axis, Pinch Tooling) – 1” capacity

- 1 Eurotech 420SLLY – 1 3/4″ capacity

- 3 Eurotech B465-T2/Y2-Trofeo – 2 3/4″ capacity

- 7 Eurotech B465-T3-Y3 – 2 ¾” capacity

- 10 Eurotech B436-Y2 Rapido – 2 ¾” capacity

- 2 Hardinge GT – 1″ capacity

- 1 Miyano ABX-51THY – 2″ capacity

- 2 Miyano BNA-42DHY – 1 5/8″ capacity

- 3 Star SB20R IV

- 7 Star SR10-J

- 2 Star SR-10J Type C

- 6 Star SR20R IV

- 2 Star SW12-R11

- 12 Tornos Deco 10 – 3/8″ capacity

- 4 Tornos Deco 13 – 5/8″ capacity

- 5 Tornos EvoDeco 10 – 3/8” capacity

- 2 Tornos EvoDeco 16a – 5/8″ capacity

We use FMB, IEMCA, Cav and Tornos bar loaders.

Tool Room Equipment

- 2 Bridgeport Model J Vertical Milling Machines

- 2 14″X40″ Tool Room Lathes

- 2 Brown And Sharpe 6 X 18 Surface Grinders

- 7 Agathon Diamond Wheel Tool Grinders

Capacity

Swiss Automation, Inc. is capable of small, medium, and large runs and shorter lead times due to our ability to run production 24 hours / 7 days a week.

Inspection Equipment

- (9) 14″ O.G.P. Optical Comparators with DRO 4 CCP CC-14 Optical Comparators

- 16 Surface Plates with Height Gauges

- 800+ Assorted Micrometers, Dial Micrometers, Pin Gauges

- 6 Mitutoyo profilometers – (surface roughness measurement)

- Model SJ400 30 Nikon SMZ645 Microscopes 8X to 50X

- 1 O.G.P. Programmable Smart Scope Video Coordinate Measuring Machine

- 1 Mitutoyo RA-400 Roundness & Cylindricity checker

- 3 Mantis Magnified Viewers

- 1 Oasis Core Inspection System

- 3 Oasis CoreX2 Inspection Systems

- 1 Hommel Opticline

- 2 Keyence IM-6601E

- 1 Keyence IM-7020

- 3 Tesa 730063 6 Universal K1-10

- 3 Universal K2-10, 1 Mitutoyo SV3100H4

- 8 Mitutoyo TM-505

Secondary Equipment

- 20 Drill Presses 1/2″ Capacity with Production Tables

- 2 Nichols Production Horizontal Milling Machines, 5HP

- 2 Hardinge HC Chuckers

- 2 Sweco Vibratory Finishing Machines:

- 1 Giant Finishing Vibratory machine

- 1 through 5-Gallon Capacity

- 1 Sunnen Production Hone

- 4 Hardinge Speed Lathes

- 1 IFP KP150 Ultrasonic Cleaning Machine

- 1 IFP KP50 Ultrasonic Cleaning Machine

- 2 Kennametal C-250 Thermal Deburr Machine

- 1 Haas CNC Mill 1 Lewis 3024-SH Ultra Sonic Cleaner

- 6 Trinco Blasters

- 3 Clemco Blasters

- 1 Comco Microblaster

Programming Equipment

- Parts Maker® CAM for Swiss-type CAD/CAM Software

- Esprit CAM programming Software

- Ultra-Edit Code Editor Software

- SolidWorks Premium CAD Software

- Cimlinc Software